Modern warehouses and logistics centres are under pressure to ship faster, handle more SKUs and support both manual operations and automated equipment such as AGVs. WMS and barcode systems give good transactional data, but they only know where a pallet was last scanned — not where it is right now. When an urgent order is released, supervisors still rely on radio calls and walking the aisles to find the right pallet, cage or cart.

At the same time, AGVs, forklifts and manual pallet jacks are sharing the same aisles and staging zones. A single stalled AGV in a narrow aisle can block several others. Busy loading docks easily become congested when trailers, pallets and empty racks are not in the expected locations. Cycle counts and investigations into inventory discrepancies consume valuable time for warehouse managers.

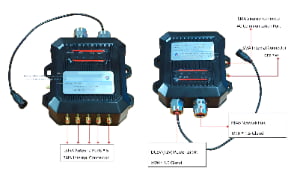

The Warehouse Asset RTLS solution uses UWB anchors and wireless beacons installed along aisles, staging areas and dock doors, together with rugged UWB asset tags mounted on pallets, cages, returnable containers and mobile racks. AGVs and forklifts carry vehicle terminals that provide precise position and heading. The RTLS platform shows live locations of vehicles and assets on a warehouse map, with search tools, geofenced zones, dwell-time analytics and simple alerts.

This approach gives the operations team a dynamic picture of where inventory, carriers and material-handling equipment actually are — not just where they were scanned. It helps to cut search time, keep AGVs flowing, improve dock utilisation and support safer mixed operations between people, forklifts and automated vehicles.