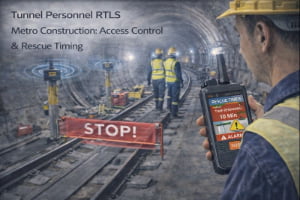

Tunnel and underground projects are some of the most challenging environments for safety management. Crews work in long, narrow headings with poor visibility, heavy equipment, and changing ventilation conditions. Supervisors need to know who is in the tunnel, where they are, and whether they are moving normally at any point in time – especially when blasting, lining, or night‑shift operations are in progress.

This solution uses UWB centimeter‑level positioning combined with dual‑channel tunnel anchors, wireless UWB beacons, and worker wearables mounted on helmets or safety vests. The system builds a one‑dimensional corridor model along the tunnel alignment, with optional 2D positioning in caverns, cross passages, and adits. Location data is sent over wired or 4G backhaul to the GridRTLS platform, which provides real‑time tracking, e‑fence alarms, gas‑safety linkage, and emergency mustering for every person underground.

The Tunnel Personnel RTLS solution is suitable for railway and highway tunnels, metro extensions, utility and water conveyance tunnels, and cross‑harbor / river‑crossing projects. It reuses the same tag family and RTLS engine as factory deployments, so contractors can share badges and helmets across surface yards, shafts, and underground headings while keeping all movement history in one system.