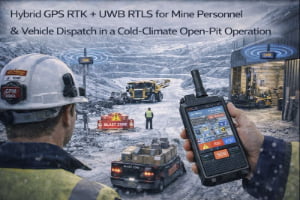

Open-pit and underground mines run 24/7 with mixed operations: haul trucks, shovels, drills and light vehicles share the same haul roads and benches with supervisors, contractors and maintenance crews on foot. Visibility can be limited by dust, weather and terrain. Dispatch centres often rely on radio calls and manual logs, and it is difficult to know exactly where people and vehicles are at any moment.

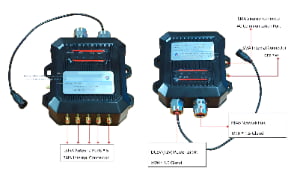

The Mine Personnel & Vehicle RTLS and Dispatch solution combines GPS/GNSS RTK with UWB to build a real-time location and dispatch layer for mining operations. In open-pit areas, a site RTK base station provides centimetre-level corrections to vehicle-mounted positioning terminals on haul trucks, loaders and service vehicles. Underground and tunnel sections use UWB anchors or wireless beacons installed along ramps and headings; personnel wear UWB or hybrid tags integrated into helmets or ID badges.

All positions are fused onto a single 3D mine map in the RTLS platform. Dispatchers can see which equipment is working where, who is in each zone, and whether anyone has entered restricted or blasting areas. The system can trigger alarms for man–vehicle conflicts, speeding and unauthorised entry, while also feeding structured data into production and safety reports.