Gantry cranes and yard stackers are the core equipment in container yards, steel coil yards and large outdoor storage areas. Operators move heavy loads between blocks, lanes and stacks under time pressure, often with limited visibility of exact positions. Yard management systems may know which task should be executed, but not always where the crane or stacker actually is at the moment of pick and drop.

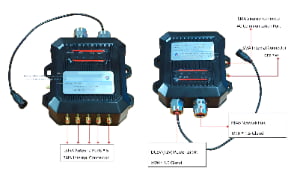

The Gantry Crane & Yard Stacker RTK Precision Positioning solution uses GPS/GNSS RTK combined with UWB to provide lane-, block- and stack-level positioning for mobile yard equipment. A site RTK base station broadcasts correction data, and each crane or stacker carries a vehicle-mounted RTK terminal that calculates its precise position in the yard coordinate system. UWB anchors or beacons can be added around stacks, rails and key structures to stabilise performance near tall stacks, buildings and under crane girders, where satellite geometry is challenged.

With accurate positions available in real time, the system can automatically record pick/drop locations, highlight deviations from planned slots, and feed live positions into your TOS, WMS or yard management system. Over time, managers gain objective data on crane utilisation, rehandles, slow zones and bottlenecks, and can adjust yard layout and operating rules based on facts rather than estimates.