Forklifts and industrial vehicles are essential for moving materials, but they also create some of the highest risks in warehouses and factories. Drivers work under time pressure in narrow aisles and busy yards; pedestrians step into shared lanes; visibility is often limited by racks, stacked pallets and trailers. Most incidents are not due to equipment failure, but to a momentary lack of awareness.

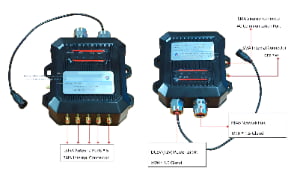

The Forklift & Industrial Vehicle Collision Avoidance solution combines UWB real-time location with on-vehicle devices and worker tags. Forklifts, tuggers, pallet trucks and other industrial vehicles are equipped with UWB-based on-board units that continuously measure distance to nearby pedestrian tags and other vehicles. When someone enters a configurable warning or danger zone, the driver receives audible and visual alerts, and—where allowed—speed can be reduced automatically in high-risk areas.

At the same time, the same UWB infrastructure can feed a central RTLS platform, so safety and operations teams can see how vehicles and people move through the site: which aisles see the most interaction, where near-misses cluster, and whether speed and zone rules are respected. This solution can be introduced step by step: starting with local vehicle–pedestrian alerts, and then adding RTLS-based analytics and reporting as needed.