In most factories there are hundreds or thousands of movable tools and material carriers that are critical for everyday production: special jigs and fixtures, torque tools, calibration instruments, welding equipment, lifting gear, returnable containers, pallets and kitting carts. These assets move between tool cribs, workshops, production lines and maintenance areas all day long.

When a key tool goes missing, a line can be blocked for minutes or hours while people search the last known locations. High-value tools and gauges occasionally disappear or are left in the wrong area. Inventory audits depend on manual counts and paper lists. It is also difficult to prove how intensively each tool is used, or whether it has stayed too long in a repair bay.

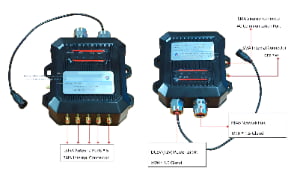

The Factory Tool & Material Tracking RTLS solution uses UWB anchors and wireless beacons installed across the plant, combined with rugged UWB asset tags mounted on tools, tool carts and material carriers. The system shows the live location of tagged items on a plant map, with search functions, zone-based rules and dwell-time analytics. Engineers and supervisors can quickly find the nearest available tool, see where kitting carts are parked, and receive alerts when assets are misplaced or stay too long in critical areas.

For greenfield factories the RTLS can share the same infrastructure as personnel and vehicle tracking. For existing plants, wireless beacons and battery-powered asset tags make it possible to retrofit without extensive cabling.