Hazardous areas in chemical plants and tank farms are tightly regulated, but day-to-day supervision is still difficult. Operators, contractors and maintenance teams move between process units, pipe racks and tank bunds; visibility is often blocked by equipment, and traditional badge readers only record gate events.

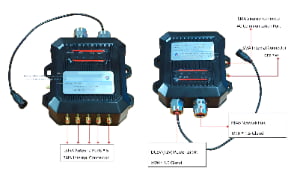

The Hazardous Area Personnel Real-Time Location System (RTLS) uses ex-proof UWB anchors and hybrid positioning tags to track personnel in real time across tanks, loading bays, pipe corridors and control buildings. Anchors such as SN2, SW and STD are certified for industrial environments and provide sub‑meter UWB coverage; wireless beacons (WX/XB) extend coverage into remote bunds and outdoor tank fields without additional cabling.

Workers wear UWB wristbands, badges or hybrid safety helmets. The positioning platform displays everyone on a 2D/3D plant map, enforces electronic geofences for Ex zones, and records full history for audits. In an emergency, the system shows who is still inside each zone and where they were last seen, supporting fast evacuation and rescue.