Overview

The BQ Vehicle-Mounted Positioning Terminal (Model: HXZK-BQ) is a professional hybrid positioning device designed specifically for vehicles operating in heavy industrial environments. It integrates UWB centimeter-level positioning, RTK high-precision GNSS, global GNSS satellite positioning, and 4G full-network communication, making it suitable for real-time tracking of mining trucks, engineering machinery, forklifts, port vehicles, transport fleets, and special industry vehicles.

The device features strong magnetic mounting, IP66 protection, TTS voice output, motion detection, SOS alerts, and low-battery warnings, providing reliable performance even on high-vibration, dusty, or all-weather outdoor worksites.

Hybrid Multi-Mode Positioning System

1. UWB Precision Positioning (<30 cm)

Provides highly accurate positioning in areas where GNSS cannot be used—such as tunnels, warehouses, indoor industrial zones, and signal-blocked environments.

2. RTK Centimeter-Level Positioning (Horizontal ±3 cm)

Uses professional RTK technology to achieve surveying-grade accuracy for outdoor operations.

3. GNSS Global Positioning (2–3 m)

Supports multi-system GNSS: GPS, GLONASS, Galileo (optional BeiDou).

Ensures continuous tracking even without RTK correction.

This multi-layer positioning ensures seamless indoor–outdoor tracking.

Industrial Communication Capabilities

-

4G full-network communication for real-time uploads

-

Optional LoRa low-power communication

-

Optional 5G ultra-low latency communication

-

Supports remote monitoring and OTA management

Vehicle-Specific Design

-

Strong magnetic base for fast, non-destructive mounting

-

Anti-disassembly alarm triggers when the device is removed

-

M6 screw port for fixed installation on metal surfaces

-

Withstands vehicle vibration, shock, and harsh outdoor weather

Safety and Alert Functionality

The BQ terminal provides multiple safety features:

-

SOS emergency button

-

TTS voice broadcast

-

Low-battery alarm

-

Motion/no-motion detection

-

Real-time status reporting

-

Smart sleep and auto wake-up to reduce energy usage

Durability for Harsh Environments

-

IP66 waterproof & dustproof

-

Works under extreme temperatures (–20°C to 65°C)

-

Resistant to rain, mud, dust, vibration, and shock

This makes it ideal for:

-

Mining and quarry operations

-

Construction and heavy engineering

-

Oil & gas fields

-

Ports & logistics yards

-

Transportation fleets

-

Emergency vehicles & special operations

Application Scenarios

-

Open-pit mine vehicle tracking

-

Fleet dispatching and safety management

-

Port haulage truck management

-

Construction machinery operation analysis

-

Outdoor industrial equipment location monitoring

-

Energy and municipal engineering field operations

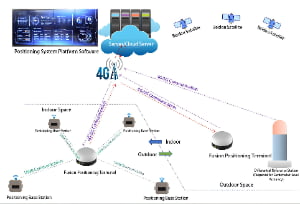

System Architecture

The BQ vehicle-mounted positioning terminal is part of a multi-layer, industrial-grade positioning and communication system. Its architecture can be divided into the following major modules:

1. Vehicle Terminal Module

-

The BQ device installed on the vehicle (strong magnetic mount or M6 screw mount) receives vehicle power (DC 12–24 V) and has internal battery (3000 mAh standard, 5000 mAh optional).

-

It integrates UWB module, RTK GNSS module, GNSS antenna, motion sensors, anti-disassembly alarm circuit, TTS voice system, SOS alert button, and 4G/5G/LoRa wireless communication.

-

It collects data: positioning (UWB/RTK/GNSS), motion state (moving/stopped), vehicle status, and sends via wireless link to server.

-

Protection: IP66, –20 °C to +65 °C, 0–90% RH.

2. Local Communication & Edge Layer

-

The vehicle terminal transmits data in near-real-time via 4G full network access. Optional modules enable 5G or LoRa for longer range/low-power use cases.

-

For UWB indoor or near-vehicle base-station zones, the terminal may interact with UWB base-stations deployed at site to refine positioning data (<30 cm accuracy).

-

The system architecture supports both on-vehicle local storage/cache (for offline operation) and cloud uplink when connectivity returns.

3. Cloud / Server Platform Layer

-

Data from all deployed BQ terminals (fleet of vehicles) are aggregated into the central server or cloud platform.

-

Key functions:

-

Real-time vehicle location display (RTK / UWB / GNSS fused)

-

Motion status monitoring (moving, stopped, anomaly)

-

Anti-disassembly / tamper alerts

-

Low-battery warnings

-

SOS event logging & voice alerts

-

Fleet management modules (vehicle assignment, geofences, zone alerts)

-

Historical playback & analytics (route, idle times, safety events)

-

4. Application & Management Layer

-

The positioning data and alerts are exposed via dashboards, mobile apps or web interfaces for operations staff, fleet managers and safety supervisors.

-

API interfaces enable integration with third-party systems: ERP, MES, safety management systems, GIS mapping, etc.

-

The solution supports rapid deployment in industries: mining, construction, port, logistics, municipal vehicles, special transport.

5. Hybrid Positioning Workflow (Indoor/Outdoor Fusion)

-

In open sky: RTK GNSS provides centimeter-level accuracy (horizontal ±3cm +1ppm; vertical ±5cm +1ppm).

-

In obstructed environments: UWB system (6.24–6.74 GHz, 1–10 Hz refresh) takes over for local high-precision zone positioning (<30 cm).

-

For general outdoor coverage: GNSS single-point positioning with 2-3 m accuracy ensures baseline tracking.

-

The terminal fuses and switches between these modes seamlessly based on environment, ensuring continuous tracking whether on vehicle in open yard, inside covered shed, or underground tunnel.

6. Vehicle-Specific Enhancements

-

Magnetic mount enables quick installation and removal for maintenance vehicles, mobile fleets.

-

Anti-disassembly alarm triggers events when device is removed without authorization.

-

DC 12–24 V power input caters to vehicle power systems; internal battery allows temporary standalone operation if mains disconnects.

-

IP66 and wide temperature range ensure rugged operation in outdoor harsh conditions such as mining, construction, and port equipment.