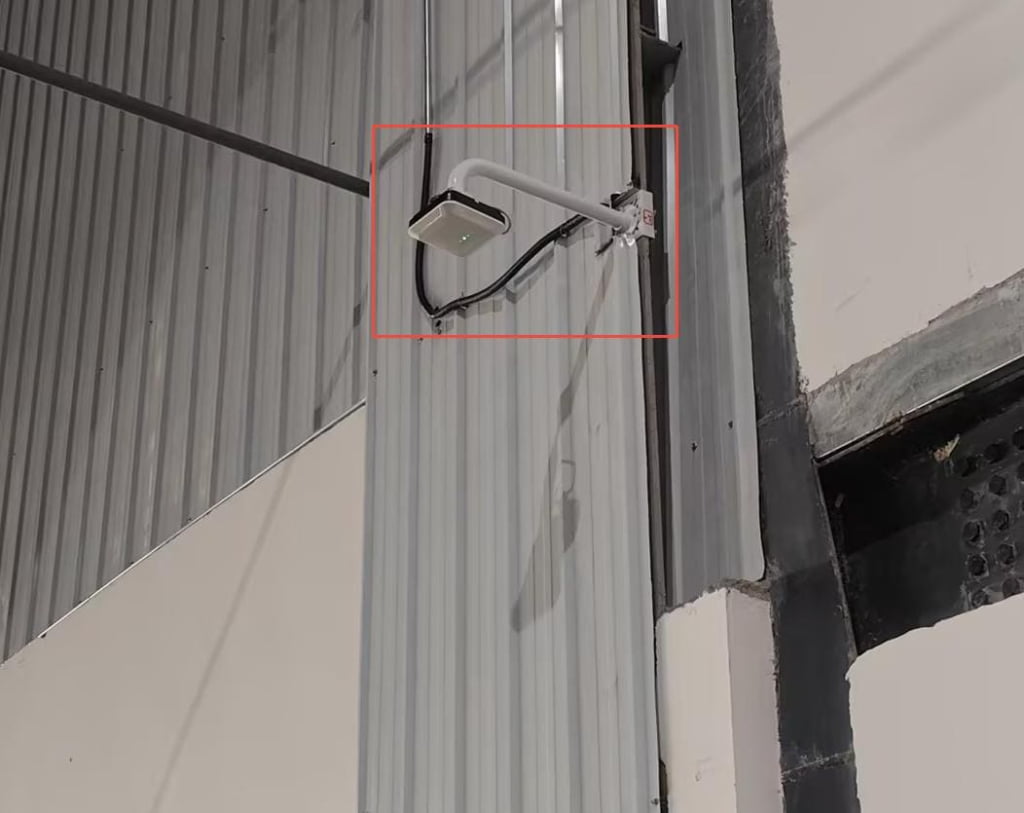

UWB Anchors

Industrial UWB anchors and infrastructure for high-accuracy indoor positioning. Synchronization, gateways and options for scalable RTLS deployments.

Supplier / Manufacturer Overview

Built for SI / Engineering Teams

GridRTLS supplies industrial-grade UWB anchors and base stations for

real-time location systems deployed in factories, warehouses, tunnels, mines,

and transportation infrastructure.

Focus area

We focus on the device & data layer of RTLS deployments—providing

anchors designed for stable synchronization, predictable geometry,

and integration with third-party positioning engines.

Our anchors are not consumer-grade beacons; they are engineered for

long-term industrial operation where uptime, clock stability, and environmental

tolerance matter more than marketing accuracy claims.

Who we work with

As a UWB anchor manufacturer and supplier, we work primarily with

system integrators, solution providers, and engineering teams

building RTLS systems at scale.

Typical deployments range from single-floor zones to multi-floor facilities and

long corridors, where anchor placement, PoE wiring constraints, and network

topology must be considered together.

Anchor portfolio & architecture

-

Wired PoE anchors and DC-powered anchors for

fixed industrial installations -

Synchronization-capable base stations supporting

pure UWB and UWB + RTK/GNSS fusion architectures -

Designed to integrate into existing Ethernet or cellular backhaul

networks -

Outputs data in formats that downstream RTLS platforms can

reliably consume

If you are evaluating UWB anchors for a new RTLS project—or replacing anchors in

an existing system—this category is intended to help you

shortlist devices, understand architectural trade-offs,

and move toward an RFQ-ready bill of materials.

Capability highlights

Designed for continuous indoor positioning in factories, warehouses, tunnels, and infrastructure projects. Enclosures, power options, and mounting methods are optimized for long-term industrial deployment rather than lab or demo environments.

Support wired PoE/Ethernet for fixed infrastructure, as well as cellular or gateway-relay architectures when cabling is limited. Power and network topology can be aligned early during RFQ to avoid rework.

Anchors are designed to work in synchronized UWB networks, where placement geometry directly affects accuracy. We provide anchor selection and BOM recommendations based on target output level (presence / 1D / 2D / multi-floor).

Anchors expose positioning data and diagnostics suitable for integration with customer platforms or third-party RTLS software. APIs, payload formats, and commissioning steps are clarified before delivery.

Each anchor configuration can be delivered with wiring references, mounting guidance, and acceptance checklists to support system integration, site commissioning, and handover.

Selection criteria (what to specify in an RFQ)

1

Target output level (presence / 1D / 2D)

⌄

Defines minimum anchor count and placement geometry. Over-specifying accuracy often increases infrastructure cost without improving operational outcomes.

2

Installation environment

⌄

Ceiling height, wall material, metal density, and NLOS conditions directly affect anchor placement and synchronization strategy.

3

Power & network availability

⌄

PoE/Ethernet availability vs. cellular/gateway relay determines anchor model selection, enclosure type, and deployment complexity.

4

Indoor-only or indoor–outdoor continuity

⌄

If outdoor tracking or handover is required, anchor selection must align with GNSS/RTK or fusion terminal strategies from the start.

5

Hazardous-area or compliance constraints

⌄

IP rating, temperature range, or intrinsically safe / explosion-proof requirements affect enclosure design and certification scope.

6

Expected lifecycle & maintenance model

⌄

Long-term fixed infrastructure vs. temporary projects change how anchors are powered, mounted, and serviced.

Customization / OEM / ODM

UWB anchors can be customized at the hardware, firmware, and deployment level depending on project scope. Typical customization requests include enclosure modifications, interface exposure, firmware configuration, labeling, and compliance alignment. Customization scope should be aligned early, as it may affect lead time, MOQ, and certification boundaries.

Material, ingress protection, mounting brackets, and connector orientation can be adapted. Changes must respect RF performance and thermal constraints.

Anchor firmware can be configured for synchronization mode, update rate, diagnostics, and region settings. Core RF logic is not modified.

Ethernet, PoE variants, antenna connectors, and auxiliary ports can be aligned with site wiring practices.

Brand labeling, packaging, and documentation can be customized for OEM projects.

Integration & architecture

Anchors are supplied as part of a device-level RTLS architecture and are not a standalone positioning system. Integration responsibilities typically include platform logic, visualization, and business rules. We provide clear data outputs, synchronization guidance, and deployment documentation to support system integrators during integration and commissioning.

Related solutions

Common solution patterns where this category is typically used.

Related industries

Where this category is most commonly deployed.

Factory, delivery discipline & real deployments

Evidence that matters to SI teams: how we lock BOMs, keep batch consistency, and ship integration-ready hardware.

Read full supplier proof ⌄

Who we are (supplier role)

Built for SI teams

GridRTLS supplies the device & data layer for industrial UWB RTLS deployments.

We work primarily with system integrators and engineering teams who need anchors and base stations

that can be deployed, scaled, and maintained in real industrial environments.

Our UWB anchors are not consumer-grade beacons. They are designed for

stable synchronization, predictable geometry, and long-term operation

where uptime, clock stability, and environmental tolerance matter more than headline accuracy.

How we deliver (from requirements to shipment)

-

Configuration first, then quotingTarget output level (presence / 1D / 2D / multi-floor) and site constraints

(PoE wiring, ceiling height, NLOS, network access) are aligned before locking a BOM.

This avoids re-quoting later. -

Integration-ready deliveryAnchors are supplied with clear integration notes and commissioning expectations.

We focus on predictable data outputs and deployment behavior, not marketing-only accuracy claims. -

Batch consistencyFor projects scaling beyond pilot, we prioritize consistent configuration and version control

(hardware / firmware / labeling) to reduce long-term maintenance risk. -

Documentation supportDelivery packs can include recommended BOM, deployment notes, and acceptance checklist

aligned with SI workflows—reducing handover friction with end customers.

Quality & reliability approach

Scope boundaries (important)

-

We supply hardware and integration-ready documentation, but

do not provide on-site installation, cabling, or civil construction. -

We do not operate a turnkey RTLS platform for end customers.

Platform development and site delivery are handled by SI / partners.

If you already have a floor plan and target output level, submit an

RFQ.

If your project requires branding, firmware parameters, or enclosure/interface changes,

review

OEM/ODM & Customization

first to align scope and timelines.

- Hardware + integration-ready documentation supplied; no on-site cabling / civil construction.

- No turnkey RTLS platform operation for end customers; platform & site delivery handled by SI / partners.

Selected based on installation environment and exposure level.

Applies to standard production models; project-specific confirmation available.

Defined per model; extended range options available for industrial sites.

Warranty terms are specified in quotation and commercial agreement.

Anchors undergo functional testing, RF verification, and configuration checks prior to shipment. For large deployments, sampling plans and acceptance criteria can be aligned during RFQ to support predictable rollout and long-term reliability.

FAQ

What is the minimum number of anchors required for UWB positioning? ⌄

For presence detection, a single anchor may be sufficient. For 1D corridor tracking, two anchors are typically required. Full 2D positioning generally requires at least three anchors with simultaneous visibility, depending on site geometry.

Do you provide anchor placement or installation services? ⌄

No. GridRTLS supplies hardware and integration-ready documentation but does not provide on-site installation, cabling, or civil construction services.

Can these anchors work with third-party RTLS software? ⌄

Yes. Anchors are designed to output data compatible with third-party RTLS engines. Integration details depend on the software platform used.

SW UWB Anchor

SN2 UWB PoE Anchor

Shortlisting UWB anchors? Get an RFQ-ready infrastructure plan.

Move from accuracy targets and site constraints to a deliverable anchor BOM, including power options, deployment geometry, lead time, and acceptance criteria.

Ready to Deploy RTLS?

Share your site layout and accuracy needs--we'll suggest a practical setup.