Limited real-time visibility of inventory and pallets

WMS knows where items should be according to the last scan, not where they actually are. Mis‑placed pallets and staging errors lead to search time, line stoppages and missed departure windows.

Warehouses, distribution centres and cross‑dock hubs run on tight service levels and slim margins. Every lost pallet, blocked aisle or forklift incident directly impacts throughput and on‑time delivery. GridRTLS uses UWB indoor positioning and GPS outdoors to give you live visibility of workers, forklifts, pallets and trailers across the entire facility.

Logistics operations are becoming faster and more complex: e‑commerce peaks, same‑day delivery, multi‑client 3PL contracts and just‑in‑time manufacturing flows. Warehouses often span tens of thousands of square metres, with multi‑deep racking, mezzanines, pick‑towers, staging lanes and busy loading docks. Forklifts and pallet trucks weave between pedestrians, while pallets, totes and roll‑cages constantly move between storage, picking, packing and shipping.

Traditional WMS and barcode/RFID systems provide discrete scan events, not continuous visibility. They struggle to answer questions like: Where is this urgent pallet right now? Which dock door is that trailer at? How close are forklifts to pedestrians in this aisle? When mis‑shipments or safety incidents occur, reconstructing the real movement of goods and people is slow and incomplete.

GridRTLS deploys UWB anchors and wireless beacons in warehouses and yards, combined with wearable tags for staff and rugged tags for forklifts, pallets, containers and roll‑cages. UWB anchors and tags typically achieve indoor accuracy better than 30 cm in line‑of‑sight areas with update rates from 1–10 Hz, enabling precise zone control and collision‑avoidance. Battery‑powered “wire‑free” beacons can run for years, making them ideal for high‑bay racking and hard‑to‑cable areas.

On a live map, supervisors see the real‑time location of all tracked objects, geofences enforce traffic and safety rules, and analytics reveal congestion, dwell times and asset utilisation. Integration with WMS, TMS, ERP, access control and CCTV turns location data into a powerful optimisation and safety layer for warehousing and logistics.

Single or multi‑building warehouses, cross‑docks and staging yards covered by RTLS.

Pickers, forklift drivers, supervisors and visitors across shifts.

Pallets, totes, roll‑cages, containers, racks and mobile equipment.

UWB-based positioning accuracy in open warehouse areas, suitable for collision‑avoidance and slot‑level asset tracking.

WMS knows where items should be according to the last scan, not where they actually are. Mis‑placed pallets and staging errors lead to search time, line stoppages and missed departure windows.

Forklifts, pallet trucks and tuggers share aisles and intersections with pickers and supervisors. Mirrors, painted lines and training help, but near‑misses still occur, especially at blind spots.

Without live visibility of trailers, containers and dock doors, planners cannot easily see which shipments are waiting, which docks are idle, or where to send the next truck.

Manual cycle counts and investigations of inventory discrepancies consume labour and often fail to explain how and where errors occurred.

Drivers, maintenance and third‑party workers move through docks, yards and equipment areas. Paper sign‑in and high‑vis vests alone cannot ensure they avoid restricted zones or follow one‑way traffic rules.

Collision‑avoidance alerts, geofenced walkways and man‑down alarms reduce the risk of forklift accidents and help meet internal safety targets.

Real-time location of pallets, equipment and trailers cuts search time, prevents staging errors and helps operations hit shipping cut‑offs.

Continuous tracking of load units and better traceability across the warehouse reduces missing items, wrong‑lane loading and costly customer claims.

Location‑based analytics show true travel paths, dwell times and congestion points, guiding layout changes, slotting and labour planning.

Warehousing and logistics operations must comply with occupational safety, traffic‑management and sometimes food or pharma handling regulations. RTLS does not replace vehicle‑safety design, PPE or racking standards, but it strengthens your safety case with verifiable, time‑stamped location and exposure data.

Industrial UWB anchors and tags with IP66–IP67 protection and wide operating temperature ranges are suitable for dry, chilled and many outdoor yard environments, and are designed to resist interference from other radios and industrial equipment.

Location data should be managed under clear policies for access, retention and worker privacy, aligned with local laws and customer requirements.

Common positioning and tracking scenarios for this industry.

Forklifts, tuggers and other vehicles are equipped with RTLS devices that measure distance to worker wearables and other vehicles. When separation falls below configurable thresholds, in‑cab and wearable alerts warn drivers and pedestrians, and all near‑misses are logged for analysis and training.

RTLS tags on pallets, totes, roll‑cages and containers provide continuous location and dwell‑time information from receiving to shipping. Planners and pickers can instantly locate urgent loads, avoid staging bottlenecks and reduce mis‑shipments.

Trailers, yard trucks and containers are tracked in real time across docks and parking areas. Operations teams can see which trailers are at which doors, how long they have been waiting and where empty trailers or containers are available.

Pickers and supervisors carry lightweight wearables. The RTLS platform captures travel paths, dwell times and time spent by zone, helping to optimise pick paths, rebalance work and improve utilisation while also enabling man‑down and SOS alarms.

Safety‑related applications such as collision‑avoidance and man‑down alerts require sub‑meter accuracy, low latency (0.5–2 s) and high availability (target ≥99.9% during operating hours). UWB RTLS typically achieves <30 cm accuracy under open line‑of‑sight with update rates up to 10 Hz, suitable for forklift and worker safety.

Wearable tags for staff generally operate for 1–3 months per charge at 1 Hz reporting, while battery‑powered UWB beacons mounted on racking or as reference points can run for multiple years, minimising maintenance overhead.

System design should include redundancy, device‑health monitoring, and practical workflows for issuing, charging and auditing tags and anchors.

The SN2 is an industrial‑grade UWB positioning anchor designed for high‑accuracy real‑time location systems. It supports Standard PoE or 12–24 V DC power, delivers sub‑meter performance (<30 cm LoS), and features an IP66 enclosure for harsh indoor/outdoor environments. Multiple mounting options (ceiling, wall, pole clamp) make deployment easy in factories, warehouses, and tunnels. Optional 4G/Wi‑Fi backhaul, AI video add‑on, and sound‑light alarm extend the anchor’s capability for safety and analytics. (Actual performance depends on anchor density, layout, and site RF conditions.)

The SW UWB Positioning Base Station is an industrial-grade device designed for sub-meter accuracy tracking of personnel, vehicles, and assets in factories, tunnels, and other complex environments.

The STD UWB Dual-Channel Base Station is an industrial-grade positioning device designed for tunnel, mining, and underground environments.

The WX UWB Wireless Positioning Beacon is a battery-powered industrial-grade UWB device designed for wireless deployment without cable installation.

The SH UWB Positioning Wristband Tag is a high-precision wearable device designed for real-time personnel tracking and safety monitoring in industrial environments such as factories, construction sites, and tunnels.

The GP UWB Positioning Employee Card is a compact, intelligent badge-style positioning device designed for industrial personnel management and safety monitoring. Built on UWB (Ultra-Wideband) technology, it achieves 10–30 cm accuracy, supports real-time location tracking, and enables instant SOS alerts via a one-touch button. The device includes vibration reminders, motion/static detection, and optional NFC/RFID, E-ink display, and LoRa communication modules. With an IP66-rated enclosure and 900 mAh rechargeable battery, it operates continuously in demanding environments such as factories, construction sites, logistics parks, and tunnels.

The UBK UWB + GPS Hybrid Positioning Badge is a rugged industrial-grade personnel tracking card designed for high-precision positioning in factories, warehouses, tunnels, and other demanding environments. It integrates UWB centimeter-level positioning with GPS outdoor positioning, features SOS emergency button, motion detection, TTS voice broadcast, 4G cellular communication, and optional NFC functionality. Equipped with a 3000mAh rechargeable battery and an IP66 protection rating, the UBK badge ensures reliable real-time personnel visibility and safety monitoring both indoors and outdoors.

The URT Hybrid Positioning Terminal is an industrial-grade wearable tracking device that integrates UWB high-precision positioning, RTK centimeter-level positioning, GPS outdoor positioning, and 4G wireless communication. It provides real-time personnel tracking, SOS emergency alerts, TTS voice broadcasting, motion detection, and optional NFC/Lora/5G expansion. With an IP66 rugged design and a 3000mAh magnetic-charging battery, the URT terminal is ideal for complex industrial environments such as factories, tunnels, construction sites, rail transit, and energy facilities.

A high-performance LPWAN-based industrial communication gateway designed for long-distance, low-power IoT communication. It supports LORA self-organizing networking, 4G cloud transmission, GPS time sync, multi-channel data forwarding, and explosion-proof applications.

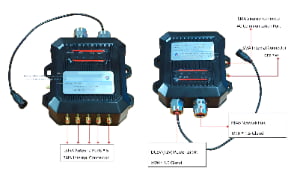

The BQ Vehicle-Mounted Positioning Terminal is an industrial-grade hybrid positioning device designed for vehicles operating in mines, construction sites, ports, transportation fleets, and harsh outdoor environments. It integrates UWB high-precision positioning, RTK centimeter-level positioning, GNSS multi-system outdoor tracking, 4G full-network communication, and features strong magnetic adsorption, anti-disassembly alarm, motion detection, TTS voice, and optional LoRa/5G modules. With a rugged IP66 design and a built-in 3000mAh rechargeable battery (optional 5000mAh), the BQ terminal ensures reliable real-time tracking and vehicle safety management in demanding industrial conditions.

The FZ Collision Avoidance Radar is a high-precision industrial anti-collision device designed for vehicles, loaders, forklifts, cranes, and mining trucks. It supports a detection distance over 100 meters, 30 cm accuracy, dual-relay output, strong anti-interference capability, and IP67 protection for harsh industrial environments.

The URTC Vehicle-Mounted Hybrid Positioning Terminal integrates RTK centimeter-level positioning, optional UWB <30 cm indoor positioning, and a GNSS full-constellation system, enabling high-precision positioning for industrial vehicles, engineering machinery, cranes, and fleet applications. With a separated-module design using coaxial cable connection, the URTC terminal achieves RTK accuracy of ±3 cm, supports 4G full-netcom communication, anti-collision functions, and performs reliably in harsh industrial environments with IP67 protection, wide temperature tolerance, and strong signal reception.

A high-precision GNSS/Beidou differential reference station that provides centimeter-level RTK corrections and sub-meter static accuracy. Supports RTCM differential data output, 4G/WiFi backhaul, UWB optional transmission, and fully integrates with positioning platforms for mining, ports, factories, and outdoor infrastructure.

The AQM Hybrid Positioning Safety Helmet is an industrial-grade smart helmet integrating UWB high-precision positioning, RTK centimeter-level positioning, GPS outdoor positioning, and 4G full-network communication. Designed for worker safety and real-time visibility, it features SOS emergency alerts, TTS voice, motion/static detection, low-battery warnings, and optional NFC / LoRa / 5G communication. With an IP56 rugged rating and a built-in 3000mAh rechargeable battery, the AQM helmet is ideal for construction sites, tunnels, factories, mining, ports, and hazardous environments requiring precise personnel tracking and safety protection.

The WZ UWB Asset Positioning Tag is a high-precision industrial tracking device designed for vehicles, tools, pallets, and other assets. It features a built-in 1800mAh rechargeable battery, powerful magnetic mounting, IP67 protection, and UWB sub-meter (<30cm) positioning accuracy. With a wireless communication range of over 100 meters, smart sleep mode, beeping alerts, and low-battery alarm, the WZ tag enables reliable asset visibility and loss prevention across factories, logistics hubs, rail workshops, and heavy-equipment environments.

Real-time forklift–pedestrian proximity alerts and zone enforcement reduced near-miss events while keeping throughput stable during peak shifts.

Centimeter-level visibility for pallets and autonomous fleets across aisles, docks, and staging zones.

Share your warehouse layout, order profiles and safety priorities, and we’ll design a UWB + GPS RTLS solution — from forklift safety and pallet tracking to yard visibility and workforce analytics — tailored to your logistics network.

Share your site layout and accuracy needs--we'll suggest a practical setup.