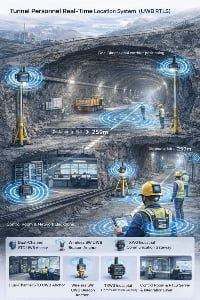

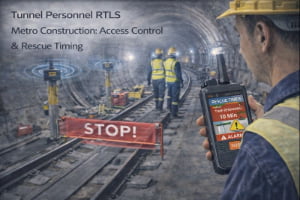

Poor visibility and limited situational awareness underground

Curved tunnels, dust and low lighting make it hard for supervisors to know exactly where crews and vehicles are located, how close they are to each other and whether they remain inside safe work limits.