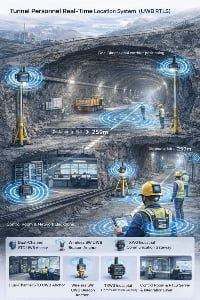

Limited real-time visibility of work crews on and near the track

During maintenance possessions, inspections and fault response, control rooms often rely on radio calls to locate crews. This makes it difficult to ensure people stay within agreed work limits and away from live lines and moving vehicles.