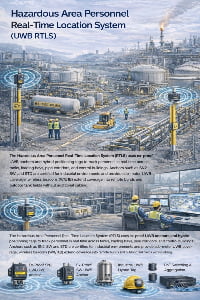

Managing personnel safety in hazardous and classified zones

Oil and gas facilities include high‑risk zones such as process units, hot work areas, high‑pressure equipment, offshore decks and confined spaces. It is difficult to know in real time who is inside each zone and whether they are authorised and properly protected.