Limited real-time visibility underground

Many mines rely on tag boards, shift lists and radio calls to track who is underground. Supervisors may not know the exact location of personnel or vehicles at any moment, especially between key waypoints.

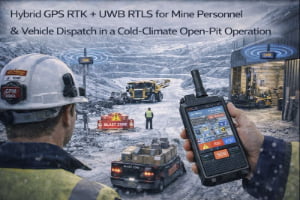

Open‑pit and underground mines are among the most challenging industrial environments — with heavy equipment, complex tunnels and constantly changing layouts. GridRTLS combines precise UWB positioning underground with GPS outdoors to deliver real‑time visibility of people, vehicles and assets, improving safety, productivity and compliance.

Mining operations span vast open pits, underground stopes and declines, processing plants, workshops, explosives magazines and stockyards. Conditions are harsh: dust, vibration, steep ramps, limited visibility and narrow tunnels shared by haul trucks and personnel. Radio coverage is patchy, and conventional tools such as paper tag boards, radios and sporadic GPS tracking cannot provide a complete picture of who is underground, where vehicles are moving or how long people remain in high‑risk zones.

GridRTLS deploys rugged UWB anchors along tunnels, levels and production areas, combined with wireless beacons and hybrid tags that also support GPS for surface operations. Industrial‑grade anchors and tags typically deliver <30 cm accuracy in open line‑of‑sight conditions with update rates from 1–10 Hz, and specialised long‑range units can cover tunnel spans up to hundreds of metres between anchors. On the surface, GPS / RTK devices on haul trucks, loaders and light vehicles provide sub‑meter to centimetre‑level tracking, even across large pits and waste dumps.

The platform presents a live map of miners, vehicles and critical assets, supports zone‑based rules (e.g. restricted headings, blasting areas, unsupported roofs), and provides man‑down and SOS alarms for lone workers. Integrated with mine‑management systems, dispatch, access control and video, RTLS becomes a central layer for safety, production monitoring and emergency response.

Underground declines, levels and drifts instrumented with UWB anchors, plus surface pits and plants.

Miners, supervisors, contractors and visitors across underground and surface operations.

Haul trucks, loaders, light vehicles, drills, service vehicles and support equipment.

UWB positioning in line‑of‑sight tunnel sections, suitable for collision‑avoidance and zone control.

Many mines rely on tag boards, shift lists and radio calls to track who is underground. Supervisors may not know the exact location of personnel or vehicles at any moment, especially between key waypoints.

Large trucks, loaders and light vehicles share narrow ramps and intersections with limited sight lines. Without accurate proximity detection, near‑misses and collisions remain a major risk.

Contractors and visitors often work in unfamiliar headings or plant areas. Paper permits and manual sign‑in cannot guarantee that they remain in authorised zones or exit promptly after work.

In fires, rockfalls or gas events, control rooms need to know who is affected, whether escape routes are clear, and which refuge chambers are occupied. Manual headcounts and radio checks can take too long.

Drills, pumps, barricades, explosives accessories and other assets move frequently between headings and levels. Misplaced items cause delays, rework and extra capital or rental spend.

Real-time underground visibility, collision‑avoidance alerts and man‑down detection help prevent accidents and support “zero harm” programmes.

RTLS-based mustering and last‑known locations speed up search and rescue, support refuge‑chamber management and provide detailed timelines for post‑incident reviews.

Continuous tracking of trucks, loaders and auxiliary equipment supports better dispatching, reduced idle time and improved use of pumps, drills and support gear.

Reliable records of underground exposure times, zone entry and vehicle movements support compliance with mining safety legislation and company standards.

Mining safety regulations typically require accurate records of underground personnel, restricted access to hazardous areas, robust emergency plans and clear evidence of compliance. RTLS enhances — but does not replace — existing controls such as tag boards, gas monitoring, isolation, ventilation and refuge chambers.

Hardware used underground must often meet standards for ruggedness, ingress protection and, in some cases, intrinsic safety. GridRTLS uses industrial‑grade anchors, beacons and tags with IP66–IP67 ratings, wide operating temperature ranges and strong EMC performance designed for harsh environments such as tunnels, processing plants and heavy‑equipment areas.

System design should be validated with mine engineering, ventilation and safety teams to ensure that antenna placement, power, cabling and wireless use comply with site policies and local law.

Common positioning and tracking scenarios for this industry.

Miners, supervisors and contractors carry UWB/GPS tags or smart helmets as they move through portals, ramps and levels. Control rooms see live positions, zone occupancy and last‑known locations, improving day‑to‑day oversight and emergency response.

Trucks, loaders and light vehicles are equipped with RTLS devices that measure distance to personnel tags and other vehicles. When separation falls below configured thresholds, audio/visual alarms warn drivers and pedestrians, and events are logged for analysis.

On the surface, GPS / RTLS devices on haul trucks, shovels and light vehicles provide live positions, cycle times and load/unload history. Dispatch and planning teams gain accurate data for productivity analysis and fuel and tyre management.

Maintenance crews and inspectors working in remote headings, pump stations, crushers or conveyor galleries wear smart helmets or wearables with UWB + GPS, motion sensors and SOS buttons. Man‑down or panic events send precise location information to control rooms and can trigger linked camera or alarm sequences.

Because mining is safety‑critical, RTLS must deliver high availability (target ≥99.99% for core functions), robust power and communications, and predictable latency for alarms. UWB anchors and tags typically provide <30 cm accuracy with update rates up to 10 Hz in open tunnel segments, while RTK‑enabled GPS devices on surface equipment provide centimetre‑level accuracy where needed.

Battery‑powered beacons and tags must offer long life; underground anchors are often powered from existing infrastructure, while tags on personnel and mobile equipment may need to operate for weeks to months per charge depending on duty cycle.

System design should include redundancy, health monitoring and clear operational procedures for charging, issuing and maintaining tags to ensure reliability during emergencies.

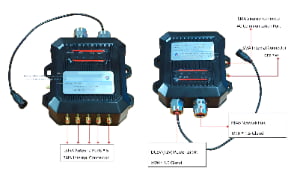

The SN2 is an industrial‑grade UWB positioning anchor designed for high‑accuracy real‑time location systems. It supports Standard PoE or 12–24 V DC power, delivers sub‑meter performance (<30 cm LoS), and features an IP66 enclosure for harsh indoor/outdoor environments. Multiple mounting options (ceiling, wall, pole clamp) make deployment easy in factories, warehouses, and tunnels. Optional 4G/Wi‑Fi backhaul, AI video add‑on, and sound‑light alarm extend the anchor’s capability for safety and analytics. (Actual performance depends on anchor density, layout, and site RF conditions.)

The SW UWB Positioning Base Station is an industrial-grade device designed for sub-meter accuracy tracking of personnel, vehicles, and assets in factories, tunnels, and other complex environments.

The STD UWB Dual-Channel Base Station is an industrial-grade positioning device designed for tunnel, mining, and underground environments.

The WX UWB Wireless Positioning Beacon is a battery-powered industrial-grade UWB device designed for wireless deployment without cable installation.

The UBK UWB + GPS Hybrid Positioning Badge is a rugged industrial-grade personnel tracking card designed for high-precision positioning in factories, warehouses, tunnels, and other demanding environments. It integrates UWB centimeter-level positioning with GPS outdoor positioning, features SOS emergency button, motion detection, TTS voice broadcast, 4G cellular communication, and optional NFC functionality. Equipped with a 3000mAh rechargeable battery and an IP66 protection rating, the UBK badge ensures reliable real-time personnel visibility and safety monitoring both indoors and outdoors.

The AQM Hybrid Positioning Safety Helmet is an industrial-grade smart helmet integrating UWB high-precision positioning, RTK centimeter-level positioning, GPS outdoor positioning, and 4G full-network communication. Designed for worker safety and real-time visibility, it features SOS emergency alerts, TTS voice, motion/static detection, low-battery warnings, and optional NFC / LoRa / 5G communication. With an IP56 rugged rating and a built-in 3000mAh rechargeable battery, the AQM helmet is ideal for construction sites, tunnels, factories, mining, ports, and hazardous environments requiring precise personnel tracking and safety protection.

The URT Hybrid Positioning Terminal is an industrial-grade wearable tracking device that integrates UWB high-precision positioning, RTK centimeter-level positioning, GPS outdoor positioning, and 4G wireless communication. It provides real-time personnel tracking, SOS emergency alerts, TTS voice broadcasting, motion detection, and optional NFC/Lora/5G expansion. With an IP66 rugged design and a 3000mAh magnetic-charging battery, the URT terminal is ideal for complex industrial environments such as factories, tunnels, construction sites, rail transit, and energy facilities.

A high-precision GNSS/Beidou differential reference station that provides centimeter-level RTK corrections and sub-meter static accuracy. Supports RTCM differential data output, 4G/WiFi backhaul, UWB optional transmission, and fully integrates with positioning platforms for mining, ports, factories, and outdoor infrastructure.

A high-performance LPWAN-based industrial communication gateway designed for long-distance, low-power IoT communication. It supports LORA self-organizing networking, 4G cloud transmission, GPS time sync, multi-channel data forwarding, and explosion-proof applications.

The XB UWB Wireless Positioning Beacon is a compact, fully wireless, and battery-powered UWB device designed for high-precision positioning without cable deployment.

The URTC Vehicle-Mounted Hybrid Positioning Terminal integrates RTK centimeter-level positioning, optional UWB <30 cm indoor positioning, and a GNSS full-constellation system, enabling high-precision positioning for industrial vehicles, engineering machinery, cranes, and fleet applications. With a separated-module design using coaxial cable connection, the URTC terminal achieves RTK accuracy of ±3 cm, supports 4G full-netcom communication, anti-collision functions, and performs reliably in harsh industrial environments with IP67 protection, wide temperature tolerance, and strong signal reception.

The BQ Vehicle-Mounted Positioning Terminal is an industrial-grade hybrid positioning device designed for vehicles operating in mines, construction sites, ports, transportation fleets, and harsh outdoor environments. It integrates UWB high-precision positioning, RTK centimeter-level positioning, GNSS multi-system outdoor tracking, 4G full-network communication, and features strong magnetic adsorption, anti-disassembly alarm, motion detection, TTS voice, and optional LoRa/5G modules. With a rugged IP66 design and a built-in 3000mAh rechargeable battery (optional 5000mAh), the BQ terminal ensures reliable real-time tracking and vehicle safety management in demanding industrial conditions.

The SH UWB Positioning Wristband Tag is a high-precision wearable device designed for real-time personnel tracking and safety monitoring in industrial environments such as factories, construction sites, and tunnels.

A high-precision GNSS-based monitoring terminal designed for real-time displacement and settlement monitoring in landslides, mining slopes, dam structures, reservoir embankments, tank subsidence, and roadbed deformation. Accuracy: ±2.5 mm horizontal / ±5 mm vertical. Supports GNSS differential positioning, 4G/RJ45 communication, fusion positioning algorithms, and outdoor IP67 deployment.

A reference deployment showing how a mine can unify outdoor RTK tracking and indoor UWB positioning to improve dispatch visibility, blast-zone clearance, and near-miss prevention.

Share your mine layout — underground levels, ramps, surface pits and plants — plus your safety and productivity priorities. We’ll design a UWB + GPS RTLS solution that covers personnel tracking, collision avoidance and fleet visibility, tailored to your mining operation.

Share your site layout and accuracy needs--we'll suggest a practical setup.