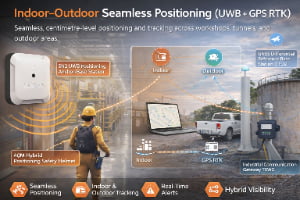

Limited real-time visibility of workers and vehicles

Supervisors often cannot see exactly where operators, maintenance staff and forklifts are working. This makes it hard to enforce safe zones, avoid congestion and coordinate responses during incidents.