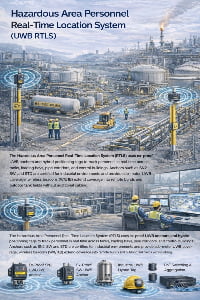

Managing worker safety in hazardous zones

Industrial and utility sites contain high‑risk areas such as high‑voltage rooms, rotating machinery, hot surfaces and confined spaces. Supervisors need continuous awareness of who is in each zone and whether they are authorised and protected.