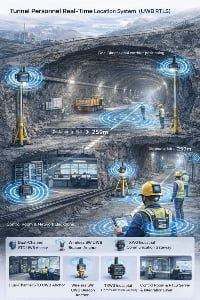

Limited real-time visibility of workers across dynamic job sites

Construction sites change daily, with rotating subcontractors and shifting work areas. Supervisors often lack precise, real-time knowledge of who is present, where they are located, and whether they are working in approved zones.