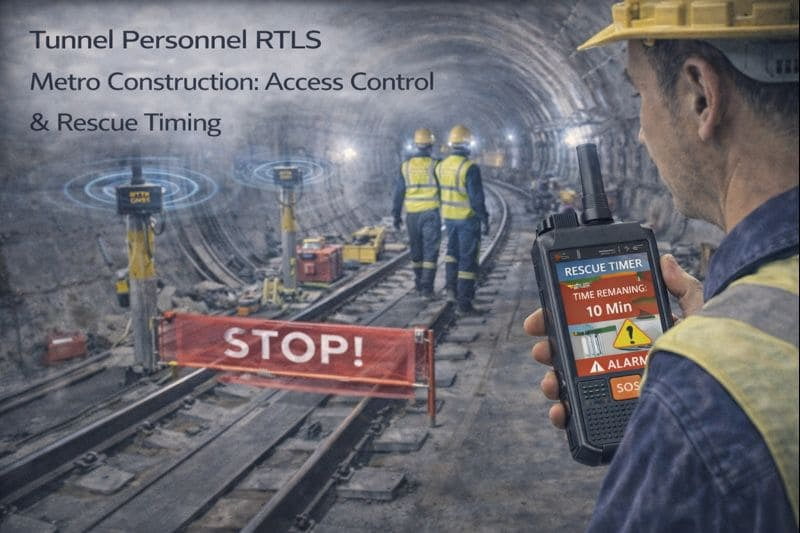

Tunnel Personnel RTLS Case Study: Metro Construction Access Control, Safety Zoning, and Rescue Timing

Real-time tunnel personnel visibility with section-level control—designed for long, linear underground construction environments.

Key Stats

KPIs (Before vs After)

| Metric | Before | After |

|---|---|---|

| Time to confirm personnel distribution underground | 25 minutes | 6 minutes |

| Accuracy of section-level personnel records | 60 % | 95 % |

| Average time to locate a specific worker during drills | 18 minutes | 4 minutes |

| Unauthorized entry into restricted tunnel sections | 6 incidents / month | 1 incidents / month |

Overview

Underground tunnel construction presents a unique safety challenge: once workers enter the tunnel, GPS is unavailable, visibility is limited, and the environment changes continuously as excavation progresses. GridRTLS deployed a UWB-based tunnel personnel RTLS that delivers real-time visibility down to the section level, enabling precise access control, safety zoning, and significantly faster rescue decision-making.

Customer Background

The project involved the construction of an urban metro tunnel section with multiple excavation faces, cross passages, and temporary refuge chambers. Hundreds of workers from different subcontractors entered and exited the tunnel daily through a limited number of portals and shafts.

Supervisors needed to answer questions such as:

-

How many people are currently underground?

-

Which section is each team working in?

-

Has anyone entered a restricted or unfinished zone?

-

If an incident occurs, who is closest and how long will rescue take?

Before RTLS, these answers relied on paper logs, radios, and experience.

Challenges

-

Linear, enclosed environment

The tunnel stretched over long distances with limited branching, making traditional zone-based systems ineffective. -

No GNSS / GPS availability

All positioning had to work without satellite signals. -

Dynamic construction layout

Sections changed as excavation progressed, requiring flexible zone definition rather than fixed rooms. -

Emergency response uncertainty

In drills, rescue teams often knew who was underground but not exactly where. -

Multi-contractor access control

Different teams were allowed in different sections at different times, but enforcement was manual.

Solution

GridRTLS implemented a UWB RTLS architecture optimized for tunnel environments:

1) Section-based UWB anchor topology

UWB anchors were installed along the tunnel at engineered intervals, creating a continuous positioning corridor. Instead of “rooms,” the system divided the tunnel into logical sections (e.g., every 50–100 meters), allowing personnel to be located by section rather than absolute coordinates.

2) Personnel positioning via wearable devices

Workers wore AQM hybrid positioning safety helmets, enabling:

-

Continuous tracking underground

-

One-button SOS alerts

-

Automatic logging of entry/exit and section transitions

3) Safety zoning and access rules

Virtual zones were defined for:

-

Active excavation faces

-

High-risk areas (blasting preparation, support installation)

-

Restricted or unfinished sections

The system generated alerts when unauthorized personnel entered restricted zones or remained beyond allowed durations.

4) Emergency and rescue support

In emergency drills, supervisors could instantly see:

-

Total personnel underground

-

Distribution by section

-

Nearest safe exits and refuge chambers

-

Estimated travel distance and time for rescue teams

Implementation

Phase 1 — Tunnel mapping and section design

The tunnel was segmented into logical sections aligned with construction phases. Anchor density was increased near:

-

Working faces

-

Cross passages

-

Emergency refuges

-

Shaft connections

Phase 2 — Infrastructure deployment

UWB anchors were mounted using tunnel-approved fixtures, with communication backhauled via industrial gateways where wired connections were not continuous.

Phase 3 — Wearable rollout and training

Personnel were issued helmets by role and contractor. Training focused on:

-

Entry/exit procedures

-

SOS usage

-

Understanding section-based alarms

Phase 4 — Operational tuning

Zone boundaries and alert thresholds were adjusted as excavation advanced, without relocating hardware—only configuration updates were required.

Results

After deployment:

-

Section-level visibility became the standard

Supervisors could see exactly how many people were in each tunnel section in real time. -

Emergency response planning improved dramatically

Rescue drills confirmed that locating workers took minutes instead of tens of minutes. -

Unauthorized access dropped significantly

Automatic alerts replaced manual enforcement, reducing violations and disputes. -

Auditability and accountability improved

Entry, movement, and dwell time data provided objective records for safety reviews and contractor management.

Overall, the RTLS transformed the tunnel from a “black box” into a managed, data-driven underground workspace.

Quote

“Before RTLS, once people entered the tunnel, we relied on radios and experience. Now we know exactly which section everyone is in. During drills, that difference alone changed how confident our rescue team felt.”<br />

— Tunnel Safety Supervisor (Anonymized)

Related Solutions

Related Products

Want a similar deployment?

Share your site type, tag count, coverage area, and safety requirements. We’ll recommend a UWB / GNSS design and a rollout plan.