Overhead Crane RTLS Case Study: Bridge Crane Positioning & Anti-Collision in a Steel Coil Warehouse

Achieve long-bay crane ranging accuracy to ±10 cm and enforce safe separation with industrial anti-collision radar—without daily calibration.

Key Stats

KPIs (Before vs After)

| Metric | Before | After |

|---|---|---|

| Crane-to-crane near-miss reports | 6 incidents / month | 1 incidents / month |

| Unplanned crane stoppage time | 14 hours / month | 5 hours / month |

| Manual spotter labor for crane crossing & coil handling | 40 hours / week | 12 hours / week |

| Damage/repair events caused by close-proximity operations | 3 events / quarter | 1 events / quarter |

Overview

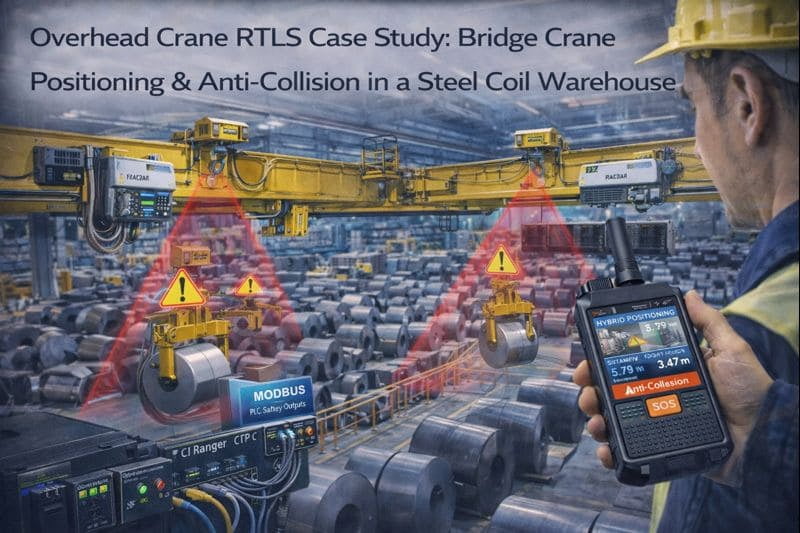

A European steel coil service center needed a safer way to run multiple overhead bridge cranes inside long, high-interference bays—without slowing production. GridRTLS delivered a crane positioning and anti-collision layer that outputs real-time distance to the crane PLC, enabling automatic speed limiting, stop interlocks, and event traceability.

Customer Background

The customer operates a steel coil receiving, slitting, and warehousing facility with multiple crane bays. Several bridge cranes share runways and frequently cross paths during coil staging and line feeding. The site runs multiple shifts, and safety requirements demand clear separation rules between cranes, coil carriers, and workers during lifting, maintenance, and bay changeovers.

Challenges

-

Long runway + limited visibility: Operators cannot always see another crane or the exact end-stop distance, especially at night or during peak staging.

-

Harsh industrial environment: Dust and water vapor are common, and electromagnetic interference from motors/VFDs can degrade weak signals.

-

No daily calibration allowed: Any solution requiring frequent alignment checks would not survive real operations.

-

PLC-ready safety outputs: The plant wanted a system that could provide deterministic distance or relay outputs to the crane control logic—not just a “dashboard.”

-

Investigation and accountability: Safety teams needed time-stamped evidence (distance, alarms, stop events) for near-miss review.

Solution

GridRTLS combined centimeter-grade UWB ranging with industrial anti-collision radar:

-

CJ Industrial Ranging Terminal (UWB distance measurement)

-

Supports 1-to-1 / 1-to-many / many-to-many distance measurement and reaches ±10 cm ranging accuracy in unobstructed conditions.

-

Designed for harsh environments with super strong anti-electromagnetic interference, IP67 protection, and can run 365×24h without requiring calibration during use.

-

Supports MODBUS_RTU / MODBUS_TCP, and can work over long distances (e.g., >1000 m with a directional antenna in unobstructed conditions) with 1–20 Hz update rates.

-

FZ Industrial Collision Avoidance Radar (safety interlock + distance output)

-

Provides <30 cm anti-collision accuracy and >100 m communication distance (unobstructed), supports RS485, and includes relay outputs (2 NO + 2 NC) for direct PLC interlocking.

-

Designed to tolerate dust/water vapor and industrial interference and can output real-time distance data for PLC or an industrial computer.

-

Operational rules (digital safety zones)

The platform supports electronic fences with configurable entry/exit rules and permission-based alarms—useful for creating “restricted lifting zones” and “maintenance lockout zones” around runways and bays.

Implementation

-

Site survey & runway mapping: Measured runway length, crane crossing points, maintenance zones, and typical blind spots.

-

Device placement design:

-

Installed CJ ranging terminals and configured distance pairs for long-bay ranging and crossing supervision.

-

Deployed FZ radars at critical approach directions to enforce hard safety thresholds.

-

-

PLC integration:

-

Distance data was delivered via MODBUS (RTU/TCP) from CJ where deterministic sampling was needed.

2025 Product Comprehensive Intr…

-

FZ relay outputs were wired into crane safety circuits for automatic speed limiting and emergency stop conditions when distance thresholds were breached.

-

-

Rule configuration: Created “no-go” crossing windows and restricted lifting zones; alarms were routed to supervisors and recorded for audit.

-

Commissioning: Tuned thresholds and update rates (1–10 Hz / 1–20 Hz options depending on the device) to balance responsiveness and stability during rapid crane movements.

Results

-

Safer crane crossings: Operators gained real-time separation awareness, and the PLC interlock reduced reliance on radio-only coordination.

-

Fewer unplanned stops: Early warnings and deterministic thresholds prevented last-second hard stops and reduced operational disruption.

-

Reduced spotter dependency: Spotters were reassigned from routine crossing supervision to higher-value safety tasks.

-

Traceable events: Safety teams could review when/where proximity thresholds were approached and how operators responded, improving coaching and root-cause analysis.

Quote

“Before, we depended on radio calls and experience to judge crane separation. Now we have objective distance data and a consistent interlock rule set. It improved both safety confidence and operational rhythm.”

Related Solutions

Related Products

Want a similar deployment?

Share your site type, tag count, coverage area, and safety requirements. We’ll recommend a UWB / GNSS design and a rollout plan.