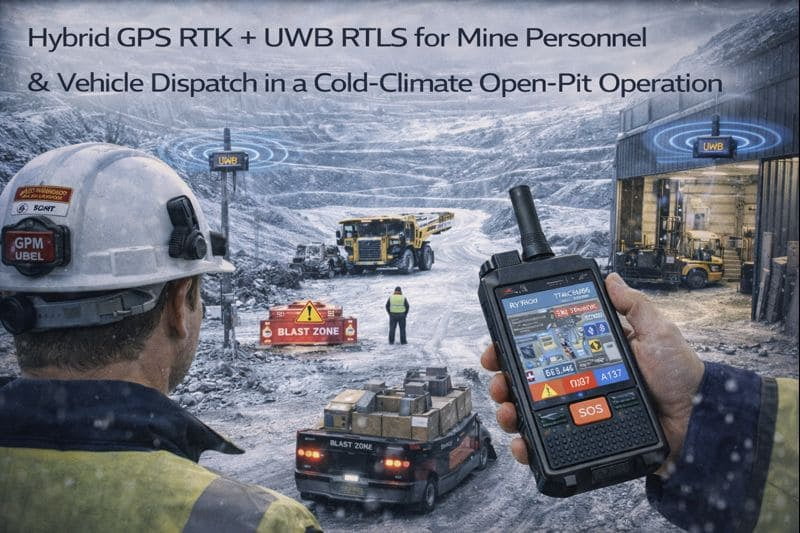

Hybrid GPS RTK + UWB RTLS for Mine Personnel & Vehicle Dispatch in a Cold-Climate Open-Pit Operation

A reference deployment showing how a mine can unify outdoor RTK tracking and indoor UWB positioning to improve dispatch visibility, blast-zone clearance, and near-miss prevention.

Key Stats

KPIs (Before vs After)

| Metric | Before | After |

|---|---|---|

| Blast-area muster / clearance drill time | 25 minutes | 8 minutes |

| Time to locate a worker after missed radio check-in | 15 minutes | 3 minutes |

| Vehicle–pedestrian near-miss incidents logged | 12 per month | 4 per month |

Overview

This reference case study describes a cold‑climate open‑pit mining operation that needed continuous real‑time location visibility for both personnel and vehicles across outdoor haul roads and indoor/covered work areas. By combining GPS RTK positioning outdoors with UWB anchors in workshops and high‑risk corridors, the site achieved end‑to‑end tracking, dispatch visibility, and enforceable safety zones—without creating new blind spots at entrances, portals, or maintenance bays.

Customer Background

The customer operates a large open‑pit mine with a typical layout: pit, waste dumps, haul roads, a crusher/conveyor transfer area, and vehicle maintenance workshops. Daily operations involve heavy mobile equipment, contractors, and frequent shift changes. Winter conditions and long travel distances between zones increase the operational cost of “not knowing where people and vehicles are” in real time—especially during blast preparation, emergency drills, or incident response.

Challenges

-

Indoor/outdoor discontinuity: GNSS works outdoors but fails or degrades inside workshops, under steel structures, and in covered corridors.

-

Blast-zone clearance verification: Manual roll calls and radio check‑ins were slow and difficult to audit.

-

Near‑miss risk at interfaces: Vehicle–pedestrian interactions peak around portals, crusher corridors, and maintenance bays.

-

Post‑incident investigation lacked evidence: Without reliable tracks, teams could not quickly reconstruct what happened.

-

Winter response pressure: Sub‑zero operations require faster, more certain emergency response and mustering.

Solution

GridRTLS deployed a hybrid positioning architecture:

-

Outdoor positioning (cm‑level): Vehicles and key personnel use RTK positioning on open roads and in the pit for dispatch visibility and route validation.

-

Indoor/covered positioning (sub‑meter to decimeter): UWB anchors were installed in maintenance workshops, portal entrances, and critical process corridors to eliminate blind zones.

-

One identity across the site: Personnel wear AQM Hybrid Positioning Safety Helmet and vehicles use BQ Vehicle‑Mounted Positioning Terminal, enabling seamless transitions between RTK and UWB zones.

-

Safety logic + dispatch logic in one platform:

-

Geofencing for blast areas, highwall exclusion zones, and restricted workshops

-

Overspeed and route deviation alerts for haul roads

-

Proximity warning using FZ Industrial Collision Avoidance Radar at high‑risk intersections and workshop entry points

-

SOS alarms and rapid “last‑seen” location during emergencies

-

-

Operational outputs: Real‑time map, replayable tracks, zone compliance reports, and shift-based statistics that can be exported for safety and production analysis.

Implementation

Phase 1 — Site survey & zone design

-

Defined safety zones (blast areas, no‑go corridors, maintenance bays, contractor boundaries).

-

Identified “GNSS shadow areas” that require UWB coverage.

Phase 2 — Infrastructure deployment

-

Installed UWB anchors in workshops, corridors, and portal areas; calibrated anchor coordinates and map alignment.

-

Commissioned RTK reference setup for outdoor positioning stability.

Phase 3 — Device rollout

-

Issued AQM helmets to high‑risk roles (shift supervisors, maintenance, blasting crew, contractors).

-

Installed BQ terminals on haul trucks, loaders, and light vehicles.

-

Deployed FZ radars at designated interaction hotspots for proximity alerts.

Phase 4 — Platform configuration & training

-

Configured alarm rules: restricted entry, overtime stay, overspeed, proximity, SOS.

-

Trained dispatch and safety teams on dashboards, muster workflows, and track replay.

Results

-

Faster blast-area clearance: Muster and zone clearance drills became measurable and repeatable, reducing clearance time from 25 to 8 minutes in standard drills.

-

Faster incident response: “Last known location” and track replay reduced time to locate missing personnel from 15 to 3 minutes in internal response exercises.

-

Reduced near-misses: Proximity alerts and enforceable zoning reduced logged vehicle–pedestrian near‑misses from 12 to 4 per month after rule tuning.

-

Better dispatch visibility: Dispatchers gained real‑time location context for vehicle utilization, route compliance, and downtime investigation—without adding manual reporting burden.

-

Auditability: Safety events can be reconstructed with time-stamped tracks and zone entries, improving post‑incident reviews and corrective actions.

Quote

“The biggest change is confidence. Before, we relied on radio and paperwork. Now we can verify zone clearance, locate people fast, and replay events with timestamps. That helps safety and productivity at the same time.” — EHS Supervisor (anonymized)

Related Solutions

Related Products

Want a similar deployment?

Share your site type, tag count, coverage area, and safety requirements. We’ll recommend a UWB / GNSS design and a rollout plan.